Next Meeting

Wednesday May 15,

7 pm at Bridges Church, 625 Magdalena Ave,

Los Altos 94024

Program

May: Spindles, one, two, too many!

Claude will demonstrate how he produced 15 identical (enough!) baluster spindles for a client. Come find out some tricks to make the workflow efficient, and with accuracy and repeatability.

President’s challenge:

May: Keep it natural!

Since most of you don’t have access to a rose engine lathe, I won’t ask you to follow in Brad’s footsteps from the last demo! Instead, bring in a piece that shows the natural edge from the tree log.

Sanding workshop

Sanding and preparation for finishing might not be your favorite part of the work, but it is often what makes or breaks the quality of your piece. And it gets easier with the right tools and techniques, so…

You are invited to a workshop/hands-on session. It is planned for Sunday May 19, 1-4pm, at the Palo Alto Adult School Woodshop located at 85 Churchill Ave, Palo Alto. Take the driveway between the playing fields, until you bump into… the woodshop. Easy to find, straight up to the building with the roll up door.

There will be tryout stations at any of the 6 lathes. You can bring in your favorite sanding tool, device, or trick. That would provide a great opportunity for members to try something they don’t have in their shop. Also, if you can, some turned pieces to practice sanding on, or your own problem piece you need help with…

Oh, and bring your dust mask, it might get hazy in there!

Upcoming Meetings

- June: ? Open to suggestions!

- July: ? Very open to suggestions!

- August: picnic

Upcoming Demos

- Sally Ault – June 9 10:00-4:00 at MakerNexus Sunnyvale, $30.00 at the door.

- Eric Lofstrom – October, details to follow

President’s Message

We’ve had a lot of great programs and meetings since we restarted our in person meets after the COVID lockdown and the dreaded zoom era. I was just compiling a list of the various programs we’ve had, many suggested by members. The diversity and breadth speaks to our openness to learn and discover new aspects of our favorite activity. But I have to say that I have nearly exhausted the list of suggested topics I have been compiling and using. So, if you have any desire or curiosity for a topic, technical, artistic or otherwise, feel free to chime in and who knows, we might make it happen!!

Claude Godcharles

Last Meeting Review

Wednesday April 17, 2024

Woodturning newsletter notes by Laura Rhodes, pictures by Angela Gunn and Roman Chernikov

Announcements

- Guests:

- Jim Koren

- Sally Ault demo, Sunday, June 9 at Maker Nexus

- Picnic – 1st Wednesday in August

- WBW Board Meeting – in early May

- Former member, Ron Seltzer, passed away last year. He donated his equipment to WBW and SVW. Look for details about a sale in June.

- Bay Area Woodworkers (BAWA) is having a fine woodworking show at Woodcraft in San Carlos, June 8-9. Entries from BAWA and non-BAWA members are welcome.

- Jim Koren knows of some madrone trees coming down. It was suggested he put the information on our Slack in the “wood alerts” section.

Rose Engine/Ornamental turning live demo with Brad Bond

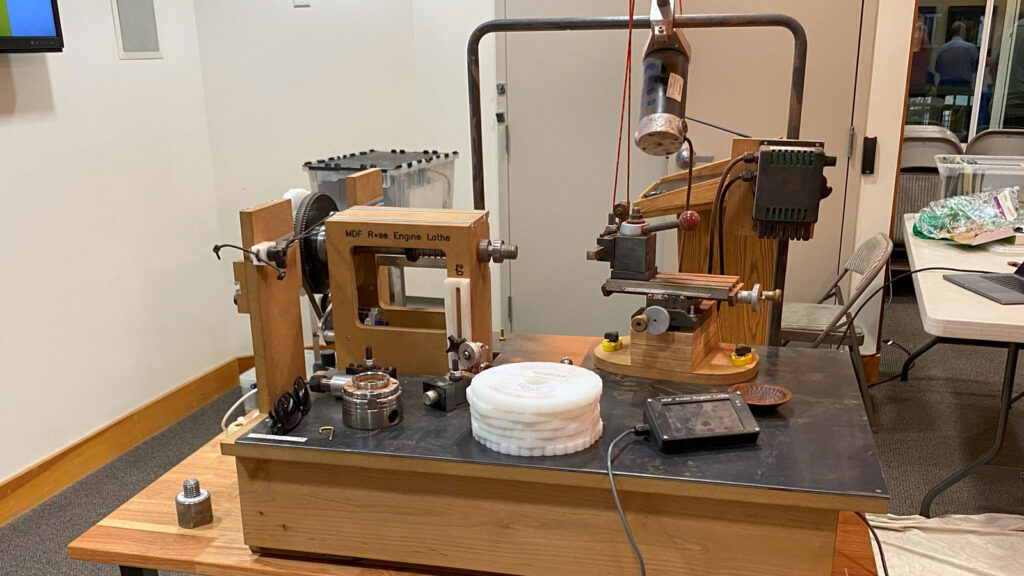

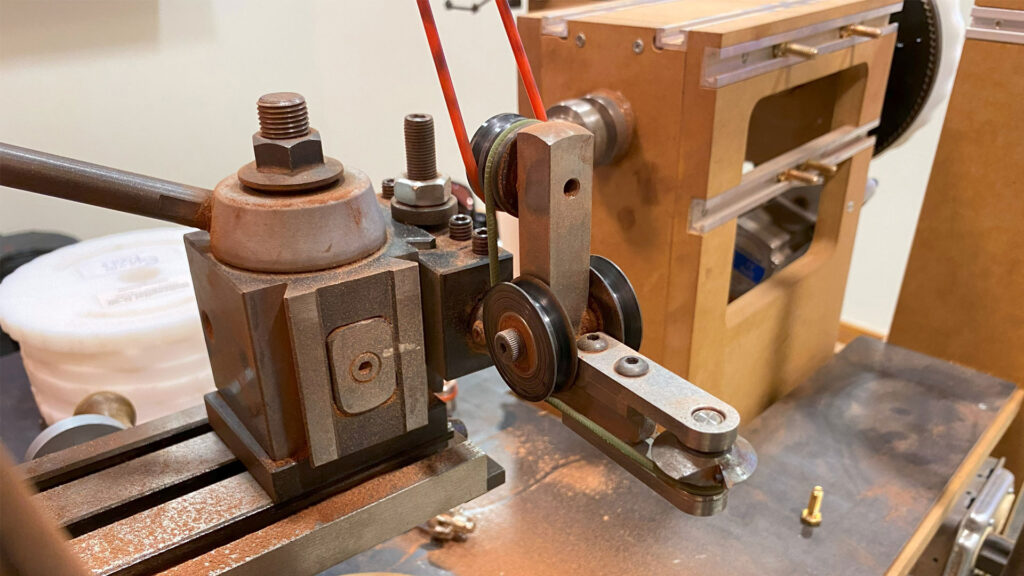

Brad Bond gave a live demonstration of his MDF Rose Engine. Brad is a member of the Silicon Valley Woodturners and documents his ornamental woodturning journey on his YouTube channel, Q Branch Woodworks. The Rose Engine is an example of Ornamental Turning where the cutters take a non-circular path to make carved patterns in the wood. Brad likened it to a 3D Spirograph (a pattern-drawing toy many of us remember from our childhoods).

The Rose Engine consists of the following components:

- Headstock – rocks back & forth, pumps in and out

- Cutter and drive system

- Can rotate horizontally or vertically.

- Can rotate elliptically.

- Can spin like a drill.

- Can be a fixed scraper.

- Rosettes (shaped cams)

- Rubbers – cam follower, can be pointed, bearing-ended, or t-shaped.

- Cross-slide – used to bring the cutter in contact with the wood, fixed to the steel bed with magnetic switches.

- Teensy 3.5 Microcontroller- based controller with touch screen to set headstock speed and potentially control other servomotors to control the cross-slide in the future.

Brad bought the carcase of his Rose Engine from Missouri for ~$4000 and has added several of his own enhancements, including an upgraded cross-slide, for ~$2000. He said that dense exotic hardwoods such as African Blackwood work best. There is a long history of ornamental turning, including the Coburg Ivories (from 1618-1632). Although most ornamental turners today are hobbyists, the Rose Engine is still used today to form a Guilloche pattern on high-end watch faces.

Brad mentioned several resources for those interested in learning more about ornamental turning:

- Plumier Foundation

- Ornamental Turners International, a virtual chapter of the AAW

- MDF Rose Engine Lathe 2.0 Library

Brad passed around several samples of his ornamental turnings and gave a live demo of carving rosette patterns on small bowls.

Presidents Challenge: Turn a lidded bowl or canister

Tom Gaston made several lidded bowls/boxes for demonstrating to his Palo Adult School turning class, including: a Poplar lidded bowl; a Teak simple cylindrical box with flat lid and finial; a Spalted apple box hollowed with Forstner bit; and a Lidded Bowl where he incorporated the holding devices (tenons) into the design.

Laura Rhodes showed a cherry box. She experienced many problems making the box, including: going through the bottom when parting off, narrowing the top so it wasn’t large enough to include marquetry because of catches while practicing using the skew chisel.

Kevin Lee made an oak bowl with lid made with oak from Kelly last month. He forgot he was going to make a lid for the bowl and made the bowl opening too large for the lid. Luckily, the green wood is still moving and the bowl deformed sufficiently to support the lid (at least at a couple points).

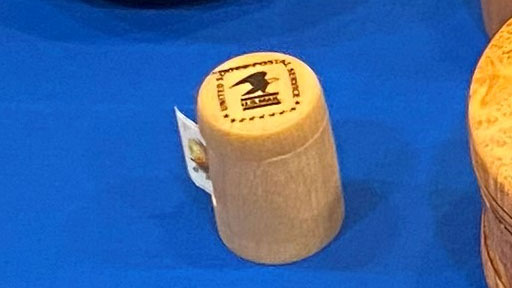

Roman Chernikov brought a postage stamp holder. He used a laser engraver to add a recognizable logo to the lid. Visit Roman’s website about chip carving, whittling, and woodturning: REA N TRY.

Nate Segraves made an acorn box of spalted holly with a Claro Walnut lid with a maple burl finial/handle.

Show & Tell:

Daniel Saal had a range of successes and failures. He had a very thin blue oak bowl, a mulberry bowl, two bowls of perhaps birch, and another bowl (with a filled hole).

Tom Mandle made a thin walnut bowl and a redwood natural edge bowl, finished with 13 coats of Polycrylic.

Tom Gaston showed a bowl made of “mystery wood”.

Jon Sauer, a self-proclaimed “Rose Engine Freak”, showed a Blackwood castle, mostly made on the Rose Engine with a turned finial. He also showed a miniature table of blackwood with an amboyna burl center on which rested a pear made of amboyna burl, pink ivory, and blackwood. To create his miniature works, John glues the wood to a waste block with super glue. The pear was sanded to 2000 grit and received several coats of super glue, followed by lacquer, followed by wax. The piece was then sanded again and finished with layers of lacquer and wax.

Visit Jon’s website: https://www.jonsauer.com/

Harvey Klein Klein made a sycamore chalice finished with Doctor’s Woodshop Polish.

Kelly Smith brought several pieces, including: a loquat burl board and bowl; a black acacia bowl, a bowl whose shape was inspired by a Tom Gaston piece; an English walnut dish; a small madrone bowl, a tulip poplar natural edge bowl, a bowl made from a Monterey Cypress tree that was a victim of a storm in Half Moon Bay, and a tree made of locust.

David Vannier got some redwood from Kelly. From one of the cores, he turned a thin bowl and pierced it with a butterfly pattern. The butterflies were also air brushed with three different colors.

Visit Dave’s website www.daves-turned-art.com.

Dan Boehmke brought two walnut bowls finished with General Finishes Salad Bowl Finish. One was of Bastogne walnut, a cross between English Walnut and Claro walnut, the other of Claro Walnut.

Brad Bond showed a cherry bowl with a spiral pattern. It was not done on the Rose Engine but rather he used the index system on his lathe to draw a rectangular grid, then drew in the spiral curves, cut the grooves with an angle grinder and then sanded the result. He also brought an eccentric bowl with a rose engine decorations on the inside.

“As the Wood Turns” by Dave Vannier

So you think you want to sell at a fair! You can tell what is consuming my time. I participate in two local Rotary Fine Art Shows, with the first being in May, and the second in August. The good news is that selling in person lets you collect a lot of good feedback. You will hear what non-turners really value, and what they don’t like. This doesn’t always result in a sale, but is still useful. Being an old engineer, i keep a lot of statistics. In general, every 4th or 5th person that comes into my booth walks out with something. Some days are really slow, and i just spend time with other artists. I’ve never been big on galleries. Yes they sell work. No they aren’t a hands off operation. But mostly, you get little or no consumer feedback. Selling does mean at times making things that I’m not inspired to do. But I tend not to do much of that kind of work. No, it’s not all roses. I spend roughly a week, setting up and getting ready. When i first started , 16 yrs ago, i just loaded up and set up. Over time, I’ve realized that marketing is required. Understanding your market demographics is really important. For example, my first show is focused more on functionality while the second show is more art focused. I’ve stopped bringing some kinds of work to each show. Just turns out to be a lot of work for no reason. I have ~60 pieces on display with another 30 as alternatives. Means having ~150 pieces to support the two shows. All this for a break even job. Fortunately i do this as a hobby. I have no idea how i could make a living doing this. Spending every weekend at a show in a different city must be terribly draining. So why do i do it? I started doing it because my wife said sell or stop making so much stuff! Now i do it, because i enjoy the interaction. But I’m not sure how much longer i can do this. So much work to get ready, pack stuff up, haul all of it around, pack it back up, and put it away. Ugh, guess my age is showing,

WBW board members and committee chairs

President: Claude Godcharles

Vice President: Tom Gaston

Treasurer: Jon Bishop

Secretary: Laura Rhodes

Member at Large: Fred Colman

Meeting Program Coordinator: Vacant (Claude G acting)

Visiting artist Coordinator: Vacant (Dean Caudle acting)

Anchor seal: Dennis Lillis

Craft Supply: Tina

Librarian: Kelly Smith

Audio Visual: Curtis Vose

Website: Roman Chernikov

Newsletter: Angela, Claude, David, Laura, and Roman

Leave a Reply