Next Meeting

Wednesday February 21,

7 pm at Bridges Church, 625 Magdalena Ave,

Los Altos 94024

Program

Finishing Part 1 – Sanding and prep!

From Bob Bley:

We have been discussing having a panel regarding finishing. Since the first step in finishing is surface preparation, we are going to break this up into two sessions.

The first session (February) will be on surface preparation/sanding (after good tool work to minimize sanding). And the second session (March) will be on the finish options and possibly finishing the finish if we have time.

Since we do not want to do too much sanding in the church where we do not have dust collection, we plan on following up the first session with another hands-on demo for sanding at the Palo Alto School which has at least five stations (Black Hole DC) to collect the sanding dust. Tentative date for the hands-on sanding event is Sunday Feb 25, 2-5pm. Details to follow.

Sanding

OK, so who loves sanding! We did not get into turning for the sanding. But it’s part of the sport so we might as well at least try to embrace it. (While trying to minimize the time we are doing it). I have actually met some folks who enjoy getting lost in this process, but I won’t name names.

We all have different ways of doing our sanding. If we described it, it might sound the same, but if we actually take a deeper dive, we might find out when we are using a rotary sander or a random orbital sander? Which size sanding discs and what size interface pads and what type of interface pads and how high of a grit do we sand to and what paper are we using. How to sand the inside of a bowl Vs the outside of a bowl. Spot sanding vs with the lathe on. Air driven or electric.

How many of us put on the first coat of finish (super blond shellac as a sealer for me) only to find out that we have some “deep” scratches we missed, so we have to repeat and over and over….

I have a small arsenal of sanders, both air driven and electric. Dave Vannier and Dennis Lillis have a different arsenal of sanders. You might have yet another selection or just one sander and are wondering which one to buy to help improve this process. There is always more than one way to do something. The three of us will host a panel discussion and we will bring an arsenal or three of sanders and relevant toys to discuss when and why we pull out what we use. A great finish is a great goal.

So, bring your questions as this should be a discussion to help everyone (and hopefully spend a bit less time sanding).

President’s challenge:

At the last meeting Tina showed us a very fine platter from Glen Lucas. Very inspiring, so let’s see who can make a nice platter for the president’s challenge!

Upcoming Meetings

- March: Finishing Part 2 – Types and application

- April: Ornamental turning live demo with Brad Bond

Upcoming Demos

- Mike Mahoney – March 10th 10:00-4:00 at MakerNexus Sunnyvale, $30.00 at the door.

- Sally Ault – June 9 10:00-4:00 at MakerNexus Sunnyvale, $30.00 at the door.

- Eric Lofstrom – October, details to follow

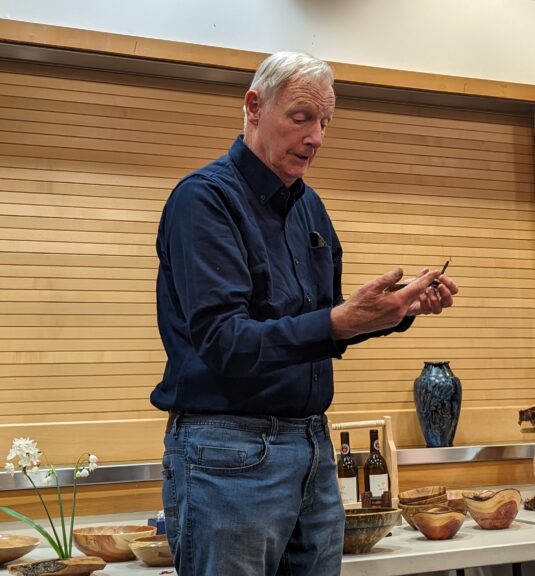

Last Meeting Review – Extended Show and Tell (or show gift from Holiday Exchange)

Wednesday January 17, 2024

Notes by Laura Rhodes, pictures by Angela Gunn and Roman Chernikov

Extended Show and Tell (or show gift from Holiday Exchange)

Jerry Galli had a hollow form make from liquidamber with an African Blackwood top. The main body received one coat of lacquer-based sanding sealer followed by beeswax. The Blackwood had a beeswax finish.

Tom Kenyon received a top made by John Sauer at the Holiday Gift Exchange. The top was made from African Blackwood, Amboyna burl, and betelnut. Tom also had several magazines he brought in for the membership to take (to avoid them going to the landfill).

Daniel Saal showed a couple of bowls from elm(?) and carob. He also had a Japanese style vase for Ikebana turned from an olive root ball.

Kelly Smith showed a set of oil-finished small bowls turned from a locust stump given to him during his Volcano sale. He presented a set of black acacia coasters in a camphor holder for his neighbor. He had to use a hand saw to cut the slits in the side of the holder and then even out and smooth the cut with rasps, files and 100 grit sandpaper. He also showed two Hollywood juniper bowls coated with polyurethane and cherry bowls (from long forgotten bowl blanks) finished with oil and beeswax.

Dennis Lillis has been busy trying to make turned lampshades. His wood of choice is aspen due to its light color and ability to let the light shine through. He had a large beautiful one with a beautiful patch of red spalting that unfortunately was knocked apart by the edge of an inertial sander while sanding the interior. Another smaller aspen shade worked well with the lamp itself with a spalted silver maple base and a thuya top.

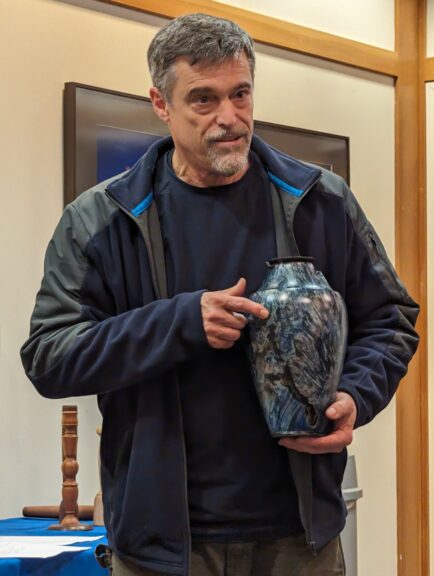

Claude Godcharles showed off his big blue vase made from box elder burl. He used a two-part dye process to highlight the grain. First he coated the piece with black india ink, then sanded back about 80%. This left the end grain dark. He then colored it with blue Trans Tint dye.

Dave Vannier has been turning for 24 years and FINALLY turned a goblet. In fact, three goblets from black acacia with long thin stems. One of the goblets had three captive rings on the stem. He reminded us that it is important when turning goblets not to have the pith centered – it would cause a very weak stem. He finished with Danish oil thinned with acetone.

Visit Dave’s website www.daves-turned-art.com.

Tom Gaston exhibited a birds-eye maple bowl. He used a multiple step dying process to show off the figure. He applied each color of dye (first blue, then green, finally red) and sanded much of it off before applying the next color. Tom also shows a small scoop which requires cutting and sanding after turning.

Jon Bishop had a set of kitchen gadgets (pizza cutter, bottle opener and bottle stopper) with CA finished turned handles. He struggled a bit with the CA finish (applying 12 coats!), but eventually wet sanded with micro-mesh pads and polished with Maguiar’s compound to achieve a beautiful shiny surface. Someone suggested that he use heavy-gauge polyethylene bags to apply the CA glue finish. Jon tapped the holes on the handles to accept the stainless-steel utensils. Jon also showed a big carob bowl. He used milliput and black CA glue to fill holes and applied General Finishes Bowl Finish.

Dean Caudle exhibited a silver maple platter but he is unhappy with the finished surface achieved with General Finishes Bowl Finish.

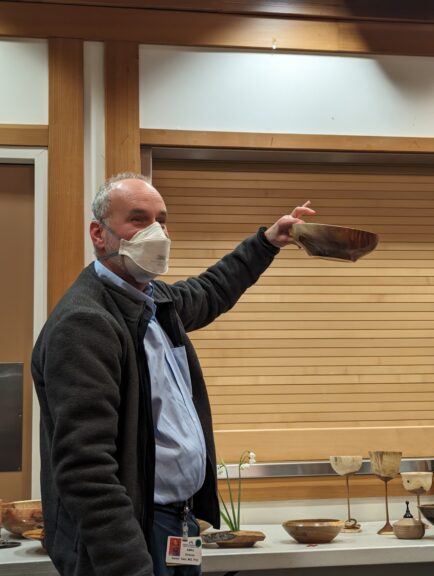

Angela Gunn showed the segmented vase she received in the Holiday Gift Exchange. She couldn’t remember who made it, but other members suggested it looked like it was made by Gordon Peterson. Angela also showed two small bowls she made. She indicated that she is struggling getting the desired curve to the exteriors of her bowls. (Sorry, no pic of Angela, she IS the photographer!)

Chip Krauskopf turned an interesting bowl from marblewood he got at the Palo Alto Adult School during our grinding session. The bowl has large wing with grooves burned into the main body. Some suggested that it could be used for chips and dip.

Roman Chernikov showed off the lantern ornament made by Harvey Klein that he won in the Christmas raffle. He also showed a snowman and Christmas tree bottle stoppers in a custom stand that he made. He gave a suggestion that when trying to paint with watered down acrylics, a woodburned outline helps to contain the paint. He also suggested that when woodburning, don’t have the heat turned up too high. Roman showed a coaster with delicate woodburned decorations.

Visit Roman’s website about chip carving and woodturning: REA N TRY.

Tina showed a work-in-progress – an oak bowl with an ogee edge that she’s not quite happy with yet. She also showed a sycamore bowl with thick walls and a too-thin bottom. She also showed a sycamore platter with beaded rim made by Glenn Lucas and a small, delicate hollow form made by Mike Jackofsky.

Kevin Lee tried his hand at thread chasing with a small acorn box. At least one of the (tapered) threads catches.

Presidents Challenge – turn a tree or a mushroom

Tom Gaston showed a tree made from very dry catalpa. After turning, he carved and then dyed the wood. He liked how the torn grain looked like blades of grass.

Kelly Smith presented a BIG redwood mushroom turned from a section of a redwood tree they had cut down in their yard. He liked the deep bark inclusions and the bark left on. He’s put on several coats of linseed oil and plans to drill out the bottom to relieve stress to prevent cracks as the large wet piece dries. Kelly also showed a collection of crooked trees.

Angela Gunn showed her attempt at a crooked tree. It was made from walnut and she successfully used the spindle gouge on this project.

Welcome our New Board Member!

Meet our new secretary Laura Rhodes. Roman passed the secretary binder to Laura after serving 5 years as the WBW secretary.

Let’s remember previous WBW secretaries/reporters: Roman Chernikov (2018-2023), Duncan MacMillan (2016 – 2017), Ken McCloud (2014-2015), Curtis Vose (2009), Steve Baum (2005-2008), Paul Williams (2005), Robert Bley (2004), Richard Winslow (2003), Gordon Rockhill (2002)

President’s Message

This new year of woodturning activities is off to a good start with great meetings, three upcoming live demos, and more hands-on sessions at the Palo Alto Adult School Woodshop. I hope everyone finds something to learn and try, and if nothing else enjoy the excellent company of the community we create! This all happens because of you: your participation, help and ideas. Don’t be shy of pitching in and be an active participants in our various areas of activity. You are all qualified and welcome to contribute! How can I contribute you may ask? Talk to any of our board members and we’ll guide you to your best opportunity. You will feel great from adding your efforts to a great team and community.

Claude Godcharles

“As the Wood Turns” by Dave Vannier

I officially renewed my CtC membership this month. Yes, I’m trying to be on a wood diet, but I’m not very good at avoiding temptation. Coming back from getting a filling in a tooth, what do I see, but a pile of wood and brush on the street in San Jose. Didn’t think much about it at first because I didn’t recognize it. The street has a lot of big old carob trees, so just to be sure, I went back the next day. Well I’m a sucker for crotch pieces, especially big ones. Most of the wood was full of termites, not just tracks, but visible critters. But the crotch looked interesting. A few cracks, but surely they don’t go very deep. Struggled to pick the piece up and ;load it into the van. As long as I’m here, there are two smaller crotches which don’t show termites. So they come home too! Oh boy, fresh wood. Means I won’t be sanding, just rough turning. The chainsaw cuts pretty easy through the big piece, although it didn’t want to stay upright for me. A little grumping, I promise no swearing (yet) and i get it cut in two. Ugh, hidden cracks, and one side is alive! So it one half is trashed, and well I’ll see how bad the cracks are. Famous last words, goes right up there with just one more cut! I open one of the other crotches, and the termites were not happy. Straight to the trash bin where I won’t bother them again. Last piece, yah I’m pretty stubborn, looked ok, except for cracks.

Day 2: cut the 3 pieces into rounds on the bandsaw, and mount the big piece on the lathe between centers. too many surface cracks to keep a natural edge, but fingers crossed. This still could be a nice 16” bowl. After taking about 4” off the blank, it looks like i still might have something. But I’m having trouble finding floor to stand on. After not having turned for more than a week, I just didn’t want to stop and clean up, so just kind of kicked it around. It’s now down to about 12” and approach dish or platter range rather than bowl. Maybe I just fill the crack, cause I don’t see the feathering I was hoping for. Finish turning it, and realize it is closer to 2 pieces of wood than 1. Don’t think I’ll waste time filing, just not got enough character to be worth it. Oh well, lets try the other 2 piece. Hmm, a nail. Great, let’s dig it out. Termites must have like it at one time, lost of tracks. Nothing alive, but more trash. I don’t want to get skunked, so we will hope for the last piece. Could be a 10” bowl. Small for me, but at least useful. Surface cracks, ugh. Turn them off, more termite tracks, turn them off, …. I got a bowl! Maybe just 5”, but I didn’t get skunked!

For those of you that are wondering what this story had to do with my CTC membership, well CtC stands for Chase the Crack! When we get too stubborn to just through junk wood away, we can spend a ;lot of time “practicing” rather than producing. I’m sure you’ve heard the saying “Life is too short to drink bad wine”. Our equivalent is “life is too short to wast time turning bad wood”. But somehow, I keep forgetting it. Kind of like my wood diet. Maybe someday I’ll learn. But please don’t hold your breath. see you at the meeting.

WBW board members and committee chairs

President: Claude Godcharles

Vice President: Tom Gaston

Treasurer: Jon Bishop

Secretary: Laura Rhodes

Member at Large: Fred Colman

Meeting Program Coordinator: Vacant (Claude G acting)

Visiting artist Coordinator: Vacant (Dean Caudle acting)

Anchor seal: Dennis Lillis

Craft Supply: Tina

Librarian: Kelly Smith

Audio Visual: Curtis Vose

Website & Newsletter: Vacant (Roman Chernikov, Claude and David acting)

Leave a Reply