23 October 2023 – Thanks to Claude Godcharles for making the Palo Alto Adult School wood shop available for the hands-on follow up to David Vannier’s “Grind, Grind, Grind” presentation at the October 2023 meeting, and to those who helped stage, mentor, demonstrate, explain, and clean up.

About 15 to 20 people attended and participated in sharpening and turning. Grinders were set up with the four bowl gouge grinds that David had featured – Ellsworth, 40/40, Michelsen, and <can’t remember>. In addition, four lathes were prepared and assigned to each type of grind so that participants could try them out and compare. Lots of one-to-one mentoring and discussion ensued.

A safety officer was on post to keep an eye on things. I suspect the bear’s name is “Dusty.”

My take aways follow.

CBN Wheels

What I heard from various folks is that wider is better, so go for the 1-1/2″ wide wheels. Wheels with side grit were favored, as it gives one a flat on which to sharpen skews. Opinions were mixed on whether a radiused edge or a square edge was better. The radiused edge sacrifices some of the accessible width. WoodTurners Wonders was the favorite source for quality and price – watch for sales.

As David Vannier noted in his presentation, equipping both sides of a grinder with CBN wheels will lead to less vibration. This will be a costly upgrade. It seemed as if the finer grades 320 and 600 might be a good choice, especially if one also has access to traditional wheels for heavy shaping.

I will probably invest in another grinder, if only because I still need to sharpen yard tools (mattock, jack hammer spade bit, et cetera) for which I will continue to use traditional grinding wheels. It saves having to change wheels. Maybe an estate sale can scratch this itch…

Gouge SET Up Blocks

I have a Oneway Wolverine Grinding System, but have never had any set up jigs. These seem to be de rigeur. Ron Brown’s Best “Gouge Set Up Blocks” will soon make an appearance in my “shop” (garage).

TAble set Up Block

Tom Gaston showed his setup for grinding without a jig. He used a Stuart Batty Angle Gauge One block to set the table angle, and some strips of painter’s tape to mark the limits of excursion on the table.

This looks to be useful, and reasonably economical.

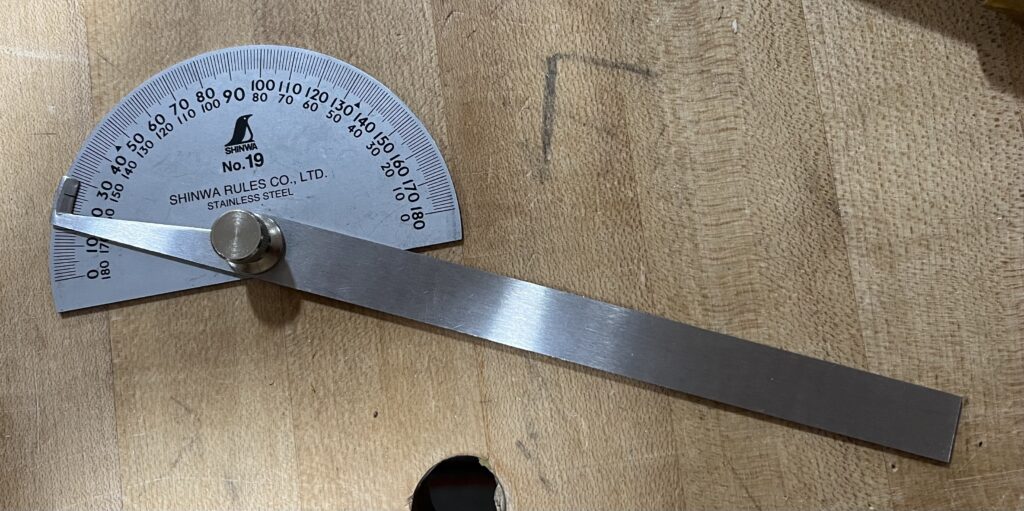

Protractor

This protractor (or one of several like it) saw frequent use to check the angles produced by the various grinds.

I might opt for a dual purpose tool such as this Depth Gauge With Protractor.

Leave a Reply